-

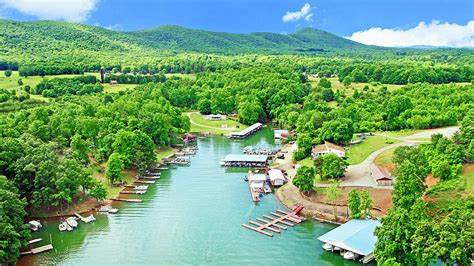

Smith Lake Concrete Services

Stamped Concrete-Pool Decks-Patios-Driveways

Interior Flooring -

We'd Love To Hear About Your Concrete Projects

Who We Are?

Smith Lake Concrete Contractors is Your Local Full-Service Concrete Company.

Concrete is a commonly used material in many construction applications around the Smith Lake region. There is a good reason, too, as concrete is durable, tough, low maintenance, reasonably priced, and more environmentally sound than many other choices. Inert, with no off-gassing issues or toxicity problems, concrete can be used for floors, countertops, pool decks, patios, driveways, and to build walls and other structures. It holds up to weather, and when mixed, laid, and cured properly, can last for years. Concrete tolerates our extremes in Alabama weather and can be finished or covered while providing insulation and a temperature sink when planned into construction. There is just a whole lot to like about concrete work done by a qualified contractor like Smith Lake Concrete Services. We are locally owned and operated, licensed and insured, and have years of experience we bring to any project you need done involving concrete.

Experienced Residential Concrete Contractors at Smith Lake, AL

While the materials can be purchased at any home center, we generally do not recommend anyone tackle concrete work that requires permanence and safety by themselves. It is a job for a qualified smith lake concrete services like Concrete Contractors Smith Lake. Concrete is extremely heavy, with a normal bag weighing in between 60 – 80 pounds. That dead weight can make anyone’s back ache, and wrestling the amount needed for most projects is a large undertaking, as concrete is also dense – meaning it takes more – usually lots more – than you think to do the job. Concrete comes in a variety of mixes with different aggregates, or is mixed custom for the application, usually a much better option for durability. Knowledge through experience tells the concrete fabricator when the mix is exactly the right texture and consistency to be poured, knowing that strength, curing, drying without cracking, aggregate raising or settling, all depend on the amount of water, reinforcement and proportions of Portland cement, sand or aggregate, and other materials. When utilized for residential projects ranging from floors to countertops to a wall down your property line, expertise leads to a quality job, cured right, looking great when done, at a good price. Call us for a free quote for your residential projects. No project is too large or too small for Smith Lake Concrete Services, Cullman AL

Free Estimate!

Smith Lake Concrete FAQ'S

If you prefer to order making a private vogue once it involves your outside living space, you’re in luck. Professionally put in concrete pool decks is quite customizable.

For one thing, ornate or tortuous style work will be fashionable decorations throughout the space. In addition, work along with your pool deck installer to use texture or alternative design options throughout the concrete area. unsmooth concrete can really facilitate the surface be less slippery and, therefore, safer round the pool.

Don’t underestimate the worth of finance within the aesthetic charm of your home’s exterior, by the way. If you wish to sell it at some point, for instance, this visual element (and the pool itself) might create a giant distinction within the property value. Even business consultants agree that curb charm is crucial for promoting a home for sale.

YES!

There are many similarities within the maintenance method of picket decks and concrete patios. each ought to be properly maintained to maximise the longevity of the surface material against the injury caused by rain, ice, heat, and cold.

Also, both wooden decks and concrete patios should be power washed and scrubbed, sanded, or ground till sleek before they will be resealed. If properly maintained, both surface varieties can last upwards of thirty years. However, the sealing material application is much less complicated for concrete when put next with wooden decks.

Concrete patios cause a definite maintenance advantage in that a 5-gallon will of sealing material covers 1,000 sq. feet, prices around $100-150, and is merely required once each 2-3 years. picket decks ought to be resealed and re-stained annually, which suggests they have to be power washed and sanded per annum as well.

Homeadvisor estimates that the majority householders pay $500-1000 on protection or waterproofing a deck. four gallons of sealant are needed to hide 1,000 square feet at a mean value of $150, and an anti-mold and mildew deck cleaner ($10-20) must be applied before the sealant.

Additionally, owners of wooden decks must additionally check for rot and mold, replace broken wood, and check for and replace disentangled nails and screws.

Overall, concrete is each easier and cheaper to maintain.

Concrete block Patios vs. Paver Stone Patios though patios shaped of stone or brick have a lower initial startup value — Land scaping Network estimates the common cost at $6-10 per square measure — pavers don’t rise up to the weather constant means that concrete can.

Concrete contractors fastidiously arrange joints within the concrete slab before they pour it to make sure its durability. Additionally, with concrete blocks, there are choices (such as steel rebar) for reinforcing concrete in geographic locations wherever soil composition makes for a poor foundation, or where extreme weather poses a threat to the integrity of the concrete.

A professionally poured concrete slab as a terrace surface won’t shift over time or sink to dirt and vegetation the way that pavers and brick do.

- Long-Lasting. One of the benefits of a Poured concrete driveway or decorative is its lower upfront cost. …

- Easy to Maintain. …

- Better Reaction to Heat and Light. …

- Better Load-Bearing Capacity. …

- No Messy Surface Issues. …

- Environmentally Friendly. …

- Highly Customizable. …

- Helps Sell Your Property Faster.

TYPES OF DECORATIVE CONCRETE SURFACES

STAMPED CONCRETE

Stamped concrete is concrete patterned and/or embossed or textured to look like:

- Stone

- Slate

- Tile

- Brick

- Wood

- Flagstone

- and various other textures and patterns

Many homeowners use stamped concrete on their:

- Driveways

- Patios

- Pool decks

- Sidewalks and

- Interior flooring

Plain concrete slabs have served because the floors fabric for basements, garages, patios, and software regions for lots years, however concrete is now additionally a feasible fabric in domestic interiors, wherein it is able to be polished, etched, or stained to function the completed floors floor. If you’re used to deliberating concrete as a utilitarian floor appropriate best for utilitarian surfaces, the numerous virtues of concrete as a ornamental floors fabric may also come as a surprise. Concrete could make a number of the maximum stylish and colorful flooring you’ve got got ever seen, aleven though they are not an excellent stylistic match for each domestic.

A concrete ground is extraordinarily sturdy and durable, and if it’s far nicely hooked up and maintained, it is able to closing for so long as you personal the house. And the layout alternatives are remarkably diverse. But concrete is likewise very tough and bloodless underfoot, and it’s far a sensible preference best wherein there may be an current concrete slab, consisting of in houses with slab-on-grade foundations, or withinside the basements of houses constructed over basement foundations. Since those flooring on “on-grade”—without delay contacting the soil—they may be prone to moisture migrating up from the floor into the dwelling space.

Concrete Floor Installation-Interior Floors

In maximum circumstances, a residential concrete ground is created via way of means of grinding an current structural concrete slab and making use of a delegated sprucing, colorizing, or texturizing technique. This can contain first getting rid of any current floors, consisting of carpeting or vinyl, to reveal the present concrete slab. Where the slab is in terrible condition, a skinny overlay of clean concrete may be poured over the antique slab; this overlay then will become the bottom floor for sprucing, colorizing, or texturing. Where a clean slab or overlay is being poured, colorizing retailers may be combined into the concrete earlier than it’s far poured. Otherwise, the staining or dyeing typically happens after the concrete has been polished via way of means of grinding with abrasive pads with steadily finer grits.

The very last step is to use a concrete sealer to shield the floor. This remedy will want to be repeated at ordinary intervals; a few specialists suggest a every year reapplication.

While it’s far extremely rare, it is also viable to put in concrete floors over a wooden-framed subfloor. Here, the technique includes pouring a skinny layer of overlay concrete over a cautiously organized subfloor, then making use of the selected colorizing and sprucing techniques. However, even a totally skinny concrete overlay is pretty heavy, and the technique frequently calls for structural reinforcement of the wooden framing.

Whether it includes pouring a clean new slab, adapting an current slab, or pouring an overlay, concrete flooring are normally hooked up and completed via way of means of professionals, because the paintings is pretty tough and calls for unique tools. Adventurous DIYers can hire grinders to hone a concrete slab themselves, aleven though this isn’t always recommended.

As lengthy because the concrete is easy and loose from holes, bumps, and defects, you’ve got got the selection of overlaying it over with any ground floor overlaying you pick at a later date. Concrete flooring permit you lots of destiny layout freedom.

Decorative epoxy flooring provides a singular combination of beauty and durability. we provide a large vary of decorative pigments and broadcast media. make a choice from multi-colored quartz aggregates, vinyl and transparent substance flake broadcast media, and golden epoxy pigments to attain a custom floor system. we tend to perceive what it takes to develop an ornamental epoxy flooring resolution for you. every floor is custom-specified, factory-made and put in supported your required performance criteria. protecting Industrial Polymers can work closely with our contractor partners to put in decorative epoxy flooring that meet your needs throughout your facility.

Epoxy floor coatings are normally used for industrial and industrial flooring. Epoxy coatings are normally applied over concrete floors to supply a high-performance, smooth, and sturdy surface that may last a few years and stand up to significant loads. several industrial sites, warehouses, and commercial buildings deem epoxy floors to keep up clean and safe conditions for workers, equipment, and inventory.

Epoxy Floor Coating blessings

Epoxy floor coatings supply many advantages in comparison to alternative ancient coatings applied over concrete:

Creates a shiny high-gloss surface that can considerably increase the brightness of interior areas

Offers a hard-wearing sturdy surface ready to stand up to significant and continuous traffic

fast and straightforward to install, requiring no layout, cutting further adhesives, or special tools or instrumentation

sturdy and easy to scrub

Ideal for warehouses and industrial applications Resists oil stains and water Creates a seamless surface that may last a few years are often combined with paints and colours to mask off chips and cracks Provides a with chemicals resistant surface ideal for producing plants Offers increased safety once the surface contains anti-slip additives are often applied in several patterns to form visible driveways and/or establish walkable areas Prevents wear and tear on existing concrete floors is also compatible with self-leveling product that may be applied over new or recent concrete, reckoning on the merchandise needs very little or no major maintenance

What Our Client Says